|

||||||||

| Xoutpost server transfer and maintenance is occurring.... |

| Xoutpost is currently undergoing a planned server migration.... stay tuned for new developments.... sincerely, the management |

|

|

LinkBack | Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

Steering Clock Spring Fix (lots of Pics)

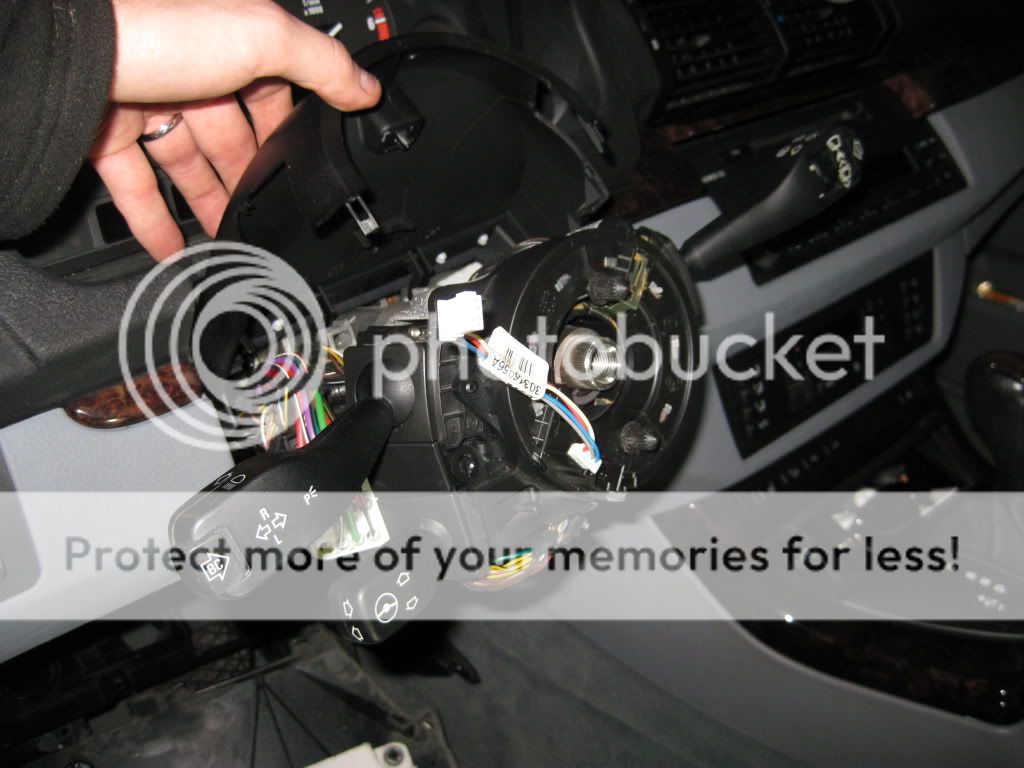

I bought a heated steering wheel from a junk yard, so my wife's hand would stay warm. She drives a 2001 4.4L X5. I knew the clock springs were different but didn't know how they worked. So when I installed the new clock spring it was wound tight. So when I turned the wheel left it broke off all the internal connections inside and stopped working. To buy a new one was about $100 i think. Because I had time I decided to take it apart and see what I could do. I read and was told by the parts guys at the deal that they cannot be fixed. But I found a way. So far its been 6 month and everything works fine.

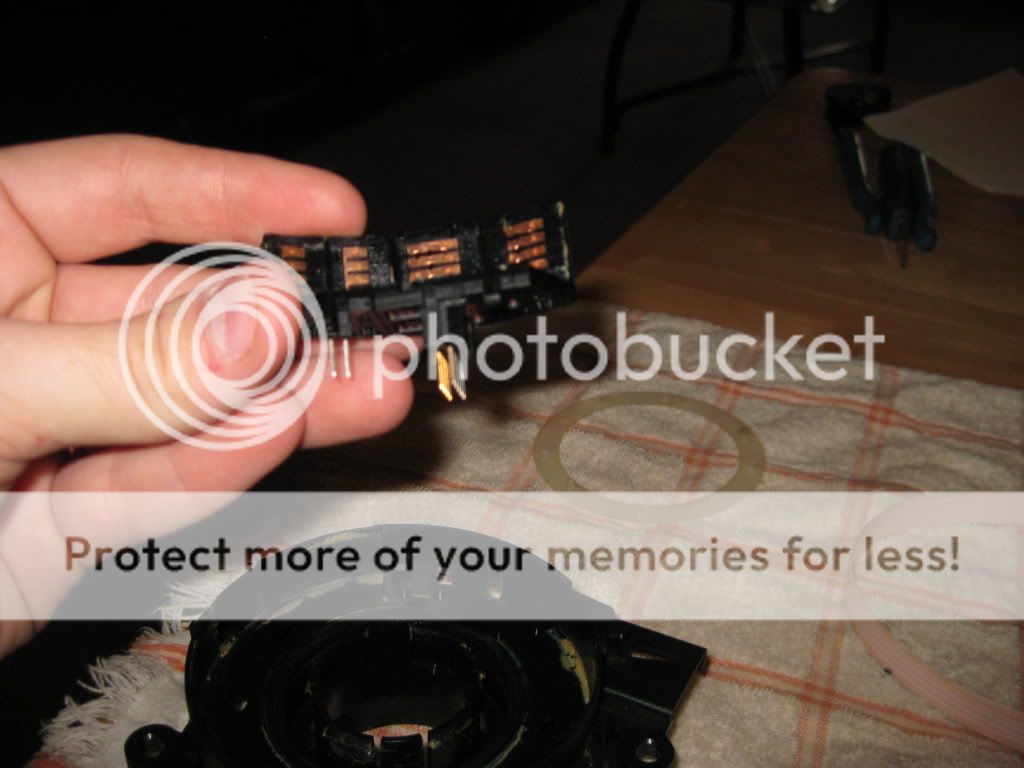

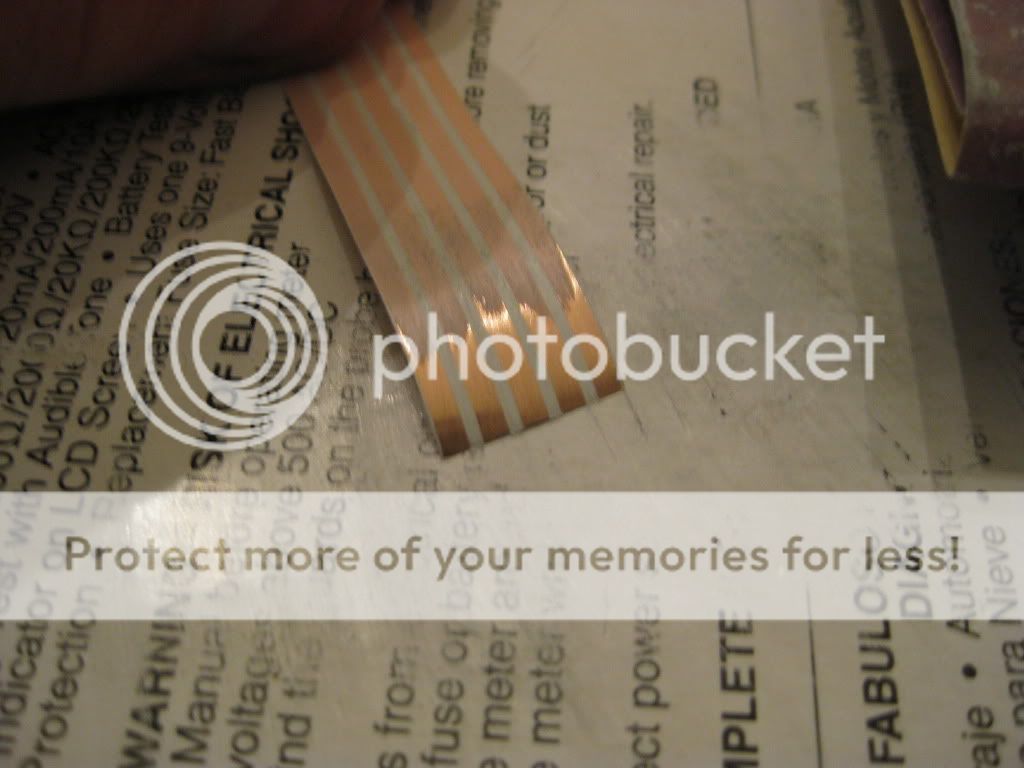

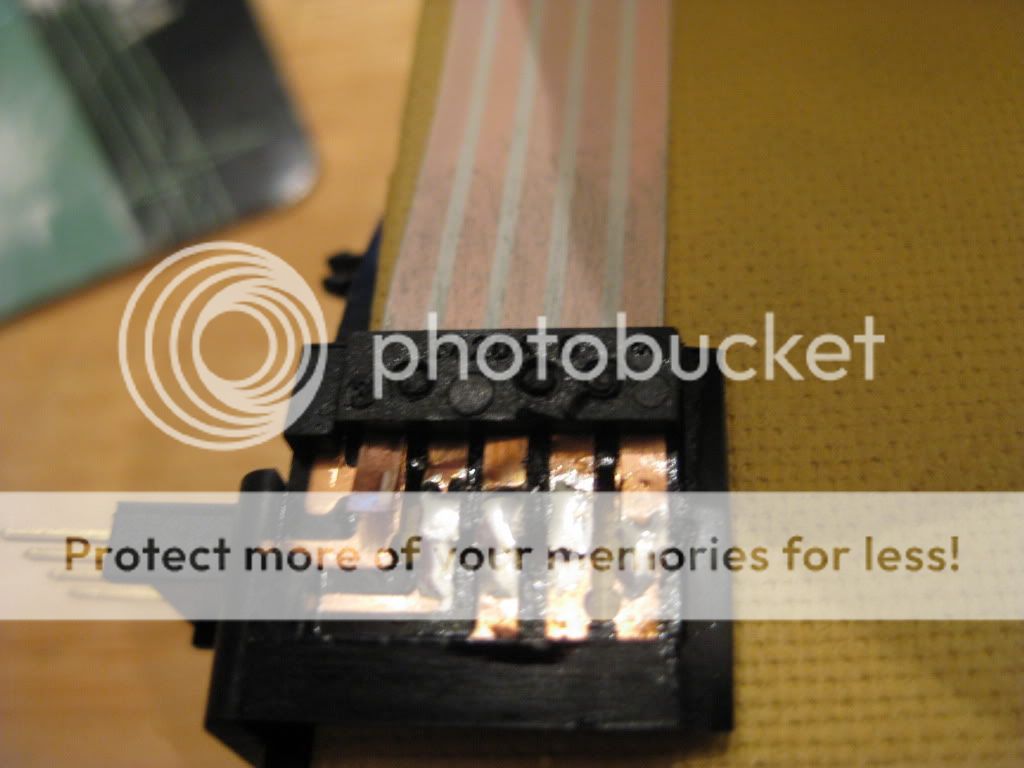

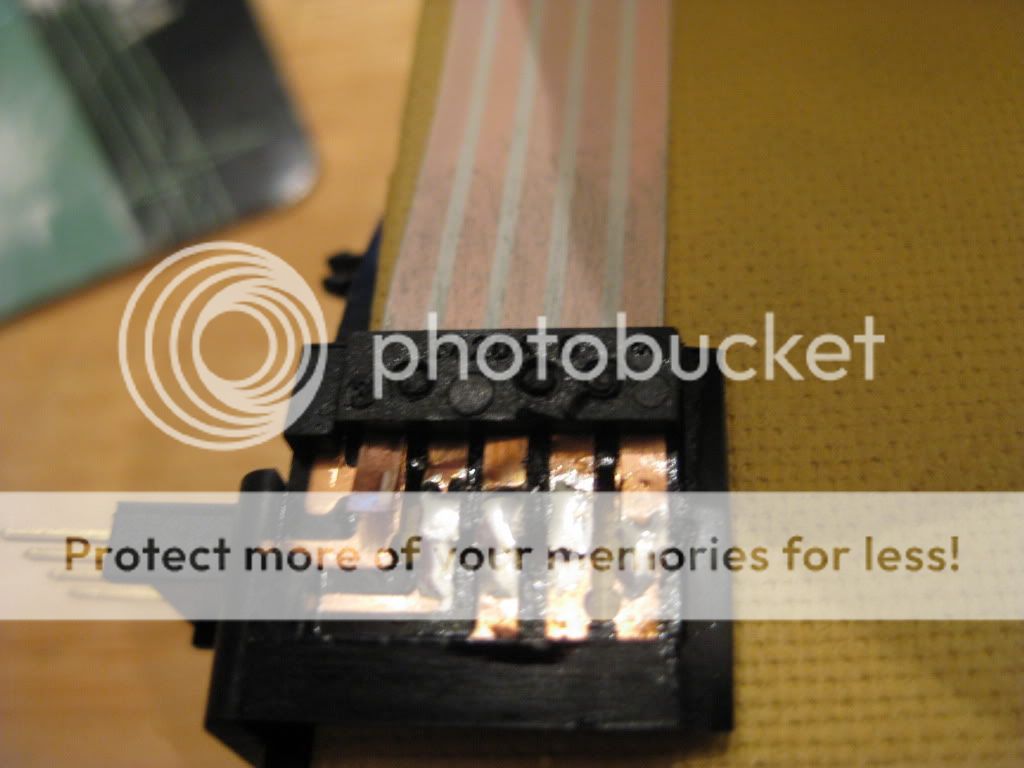

A clock spring is basically a way to wire power to the steering wheel buttons w/out the wires getting tangled or twisted when the steering wheel rotates. (I found this out).           When I finally got it apart, the wire ribbons were twisted up and some had bends in them.   This is the other half. The ribbons were supposed to be connected to that copper metal.  Took me a little while to figure out what in the world was going on and how all this worked.  I needed to find out if any of the ribbons were damaged. So I read the resistance of each individual wire in the ribbon to make sure the metal was still intact and not broken b/c of a bend or something.        This is where all 4 ribbons ripped apart when I turned the wheel. If the clock spring was not wound up all the way tight, they would have never been pulled apart.     So I sanded and stripped back the plastic so I could reconnect the ribbon to the metal.  Then I soldered the ribbon ends back to the metal.  Then glued the black plastic back over the ribbon.  Here each ribbon was re-connected to its appropriate connection.   Here I snapped all the connectors back together.  Here its all wound back up. Almost done.    All thats left is to stick it all back inside. And snap it back together.   All Done  Once I got it back in the car, it worked great. Before no green like b/c all ribbons had lost their connections. This was a very difficult and tedious process. To fix just the clock spring probably took 6-8 hrs. But would go much faster the 2nd time. I spend so much time trying to figure out what the heck was all this mess and how the heck did I get in the middle of it. I made sure when I installed the clock spring 2nd time around that it was not wound tight. From the tight position I turned it back 3 full turns. When driving it will never turn 3 full turns from center so I know there is no risk of destroying it again. Comments or Questions....let me have them

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|

|

|