|

||||||||

| Xoutpost server transfer and maintenance is occurring.... |

| Xoutpost is currently undergoing a planned server migration.... stay tuned for new developments.... sincerely, the management |

|

|

|

LinkBack | Thread Tools | Display Modes |

|

#101

|

|||

|

|||

|

Now, they didn't have the 31.090 (0735 368 074) and I ordered all the others but that. Although mine looks alright I wanted to replaced as per Phil suggestion. Now, Phil how often did you find that bearing getting bad? Last edited by fmugur; 06-08-2012 at 05:10 PM. |

| Sponsored Links | |

|

|

|

|

#102

|

|||

|

|||

|

I never really see problems with the 31.090 bearing, though - if you haven't already done so - it would be worth separating the cage from the race just to check the raceís condition Ė being very careful not to scratch or otherwise mark the rolling surface (use something plastic if possible to prise the two apart)

However, Iíve certainly seen issues with 72.150 & 72.170 before now (classic sub-surface fatigue/spalling failures)  Phil |

|

#103

|

||||

|

||||

|

Yes, the guys at Eriksson are very helpful and their shipping was very quick.

__________________

2003 4.4i black ext./black int./black headliner (kid's runabout) 2014 535d X-drive, M package, silver/black interior Sold but not forgotten: 2009 E70 35d, black ext./black int./black headliner (sold 2021) 2006 4.8iS Le Mans blue/cream int./black headliner, SOLD in 2012 sadly... Other hardware: 2015 Cayenne S (wife's new DD and definitely wroooommmmm) 2016 Tundra 1794 edition crew cab, luxo hauler 2005 Tundra crew cab, weekend hauler. Sold after 150k very happy miles. |

|

#104

|

|||

|

|||

|

What a challenge taking out the clutch springs! I had hard time finding somebody to make the tools for me. The size of the rings is not standard and it is hard to make it custom. I ended up using PVC pipes although I will have to figure out how to put back the big snap ring. I couldn't find 6" PVC pipe.

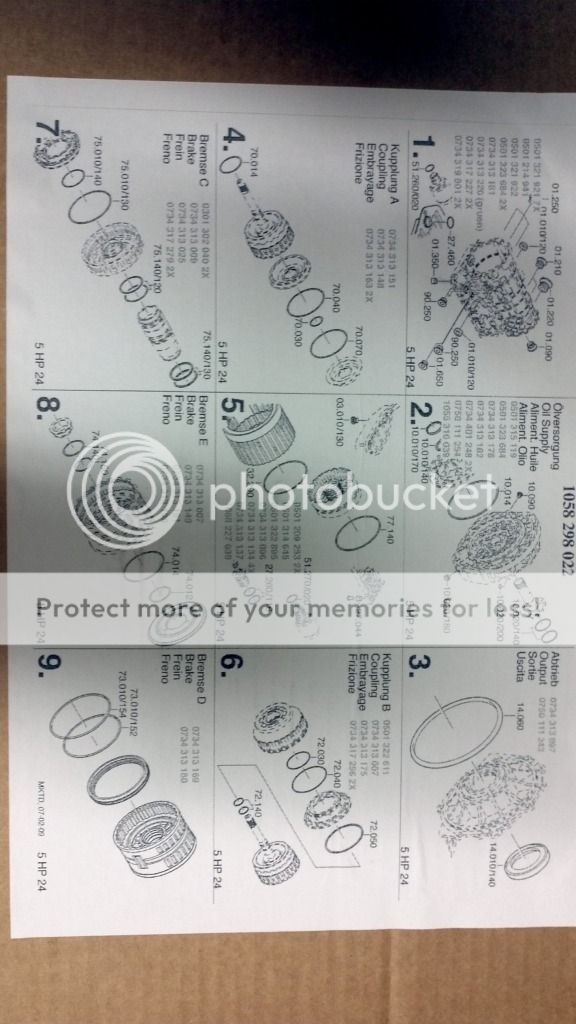

So, today I planned to finish up the transmission when I ran into a few issues. It looks like the overhaul kit I got has, for some reason, a few wrong O-rings. For example: - from the group 2 is missing 10.014 but there are a few other smaller O-rings - from group 9 is missing 73.013/152 and 73/013/154 and the same, there are a few other smaller O-rings. I wrote and email to CTSC where I bought the kit from and waiting for the reply. Should I wait to get these parts or should I go ahead and reuse the old O-rings? Any idea how is the failure rate of these O-rings? How critical is to replace these?

|

|

#105

|

|||

|

|||

|

These three O-rings are quite large in diameter so they're coiled round to fit in their packet and therefore each looks like two smaller O-rings. Have you actually opened the packet to check?

Phil |

|

#106

|

||||

|

||||

|

The biggest one is a bit of a conundrum. I think I used some strip material used for hangiing pipes which is perforated. Wrapped it a couple of times to get the strength and then put a small bolt to hold it together.

An alternative is to get some aluminium strip material 2.5 or 3mm and bend it to the diameter you need. The kits are very well prepared and I had a lot of stuff left over. Keep us posted. From a sunny beach in Fla. :-) LV

__________________

2003 4.4i black ext./black int./black headliner (kid's runabout) 2014 535d X-drive, M package, silver/black interior Sold but not forgotten: 2009 E70 35d, black ext./black int./black headliner (sold 2021) 2006 4.8iS Le Mans blue/cream int./black headliner, SOLD in 2012 sadly... Other hardware: 2015 Cayenne S (wife's new DD and definitely wroooommmmm) 2016 Tundra 1794 edition crew cab, luxo hauler 2005 Tundra crew cab, weekend hauler. Sold after 150k very happy miles. |

|

#107

|

|||

|

|||

|

That is embarrassing guys. With so many pieces i guess I tried to be too organized and take out from the bags only what was needed and since I couldn't match the size at a glance the first thought was that the package had the wrong stuff in it and it never crossed my mind that the big o-rings will coil around and look like that... Anyway that's my excuse

I will if I can resume the work tonight. Thanks for your quick replies. Last edited by fmugur; 06-18-2012 at 02:15 PM. |

|

#108

|

|||

|

|||

|

Just to double check. In the manual I found only one alignment required which is on the oil pump ring. Any other alignment I should be aware of?

What about this, does it have to be aligned? When I inserted it in the I noticed orifices that might make a diference.

|

|

#109

|

|||

|

|||

|

No, there's no particular alignment for the sun gear sleeve where it's splined into the C-clutch drum. There's an annular groove machined around the bore of the drum which carries the oil around the circumference, irrespective of the feed hole positions. Once engaged on the spline the sleeve needs a good shove to get both O-rings onto their sealing lands in the drum bore.

Phil |

|

#110

|

|||

|

|||

|

Thanks Phil. I am almost done. The two towers are ready to go in although I ended up with an extra large friction plate. I checked how many I took out and the number matches with the large friction plates I put in which is 15. Did I miss something or the kit came with 16 large friction plates?

Louis, did you end up with an extra plate as well or I screwed up somewhere? I tried to be very careful though. The second question is regarding the 0.2-.04 mm play under 200N force. I see Phil and the manual referring to this as an important check point. Did you guys do that check and if you did how did you do it? thanks, Florin |

|

| Bookmarks |

|

|

|

|